RFID Frequent and Quick Retail Inventories

Companies of every dimension regularly evaluate their capacity regarding inventory management and try to obtain the greatest efficiency from the existing infrastructues: some decide to adopt new technologies which may optimize their performance. Among these, radiofrequency identification, RFID, absolutely stands out, as it allows, as we have seen in the RFID Explained video, counting quickly with an error possibility close to zero.

Use cases and exigencies are different depending on the sector the company operates in, but it is true that they all aim at obtaining a fast and immediate photography of the products in stock, whether they be in a warehouse, store or productive site. The worst nightmare? Having to block every single activity, close a point of sale or specific area and devote many resources to obtain such datum.

Thanks to RFID it is possible to perform many fast inventories throughout the year and therefore have increasingly precise data. Having this information at hand at any time allows making strategic production and sale choices, as well as making warehouse and replenishment operations more efficient.

Let us now move specifically into the retail world: Fashion and MMR.

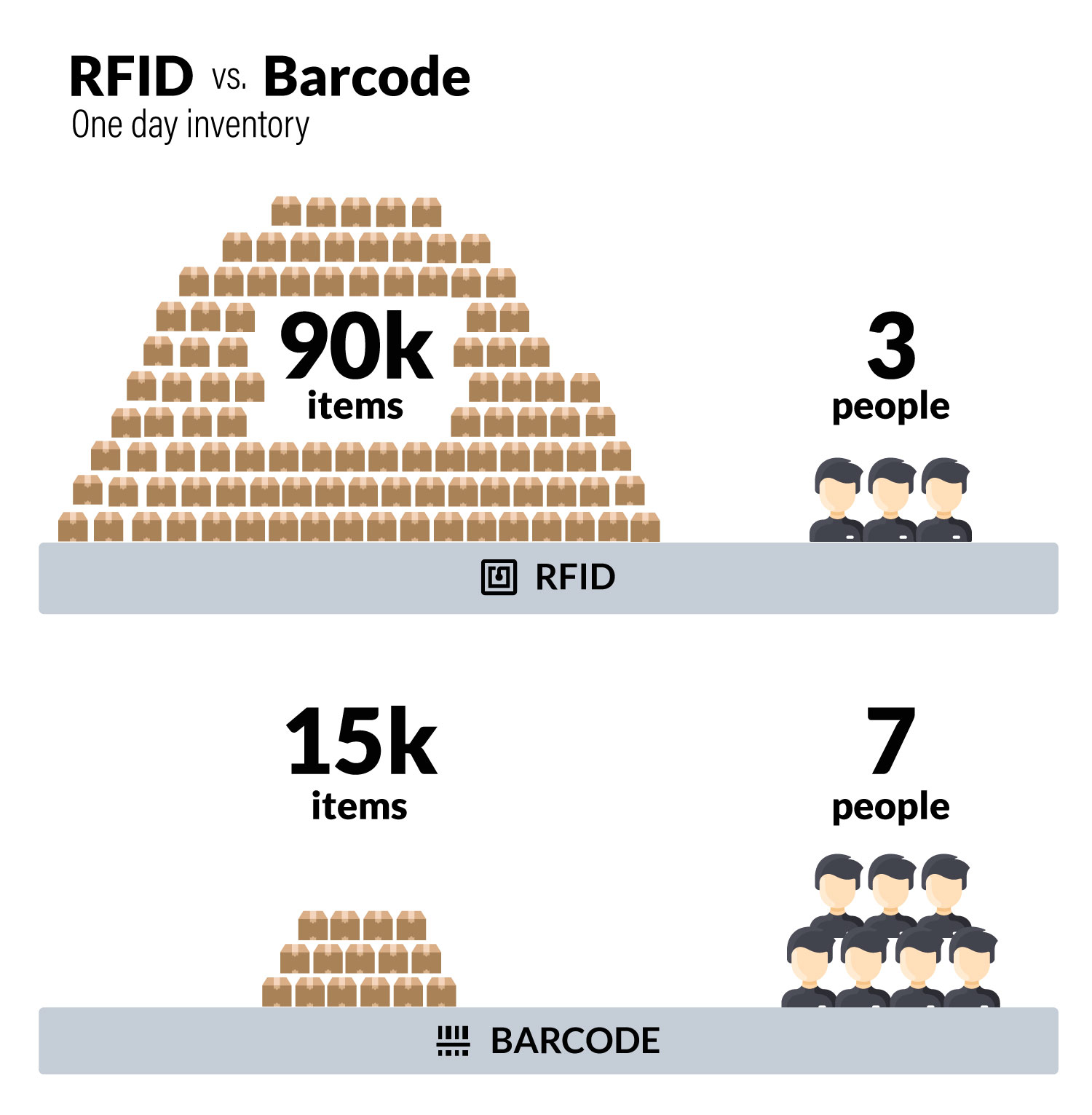

Let us start with numbers:

7 people, 1 day, 15,000 items is the time calculated by a fashion world company to perform a traditional inventory in a point of sale.

With RFID? 3 people, 1 day, 90,000 items.

These data make us reflect on the possibility of performing more data collections for items present in sale areas, in food warehouses or main warehouses. Therefore, to the annual inventory, compulsory by law, are added the so-called cyclical inventories, which allow monitoring stock status and undertaking proactive actions in the replenishment of the various areas. The sales assistants’ operativity is guided by the information deriving from these inventories: the data collected in fact merge into the store management mobile application.

At the base of cyclical inventories there is constant and continuous item traceability throughout their handling: knowing which items there are in the sale area, what has arrived into and left warehouse, what has been sold and what has been stolen, allows not missing a single sale (because the item is always available on the shelves or because the sales assistant is able to promptly answer about its availability or replenishment times), and preventing potential thefts by analyzing recurrent events.

Pinpointed inventories or inventories by area can be added to cyclical ones (e.g. children apparel): the data collected are useful to the store to correct potential discrepancies about the presence of a given item on the shelves (e.g. there must be 4 L sizes, 4 M and 8 S ones); they also feed the total inventory which, in that way, besides becoming quicker, will be more precise and will provide a reliable datum for replenishment operations.

The benefits of adopting RFID do not only concern the physical point of sale, but also those online as well as real-time availability for a given item in a certain store.

Omnichannel strategy and better inventory accurateness translate into higher profitability for the brand.

As we have explained in our post Cyclical Inventories for a More Effective Automatic Restoking, so that system algorithms for the replenishment system adopted should work correctly, it is necessary to have increasingly precise data on stock and the only way to obtain them is performing continuous and constant data collection.

There are many similarities with the fashion retail world: they can perform total inventories or do it by areas, aisles or product typology.

The combination of the data collected (stock on shelves or warehouse, sold or returned items, etc.) contribute to higher inventory accurateness, which then combines with omnichannel strategy to achieve higher profits (read also E-Commerce and Logistics Walk Hand-in-hand).

What is it that is different? In MMR replenishment velocity must be very high due to expiry dates, so price and promotion management must therefore be as fast: cyclical inventories help to have updated and precise data and to reduce out-of-stock risk.

In this world, as in manufacturing, “returning items” management assumes a certain relevance. Rollers, baskets, pallets, besides being indispensable for everyday operativity, have also got an economic value.

The utilization of RFID technology allows tracing these asstes, having therefore precise data on their availability and position.

If the benefits of utilizing RFID technology in this area have been confirmed by experiences like that of Esselunga, it is necessary to affirm its effective sustainability. Every single item should arrive bearing its identifying tag and it should be those who produce it or, better, those who do the packaging to do so.

An alternative solution already exists and is called Computer Vision: thanks to the combination of artificial intelligence and augmented reality, retailers can perform even more accurate inventories, without the need of relabelling every item.

Stay tuned!