Technical, special and medicinal gas industries generate an annual turnover of about 2.4 million euro just in Italy, according to data provided by Assogastecnici Federchimica. Production is mainly represented by oxygen, nitrogen, argon, helium and rare gases, although in this healthcare emergency period its most important commitment is medicinal oxygen to meet the requests which in certain cases have increased five-fold. If in ordinary conditions there were over a million oxygen cylinders circulating annually among hospitals, healthcare strucures, pharmacies and patients at home, nowadays they are a great lot more and tracing every single movimentation has become extremely necessary.

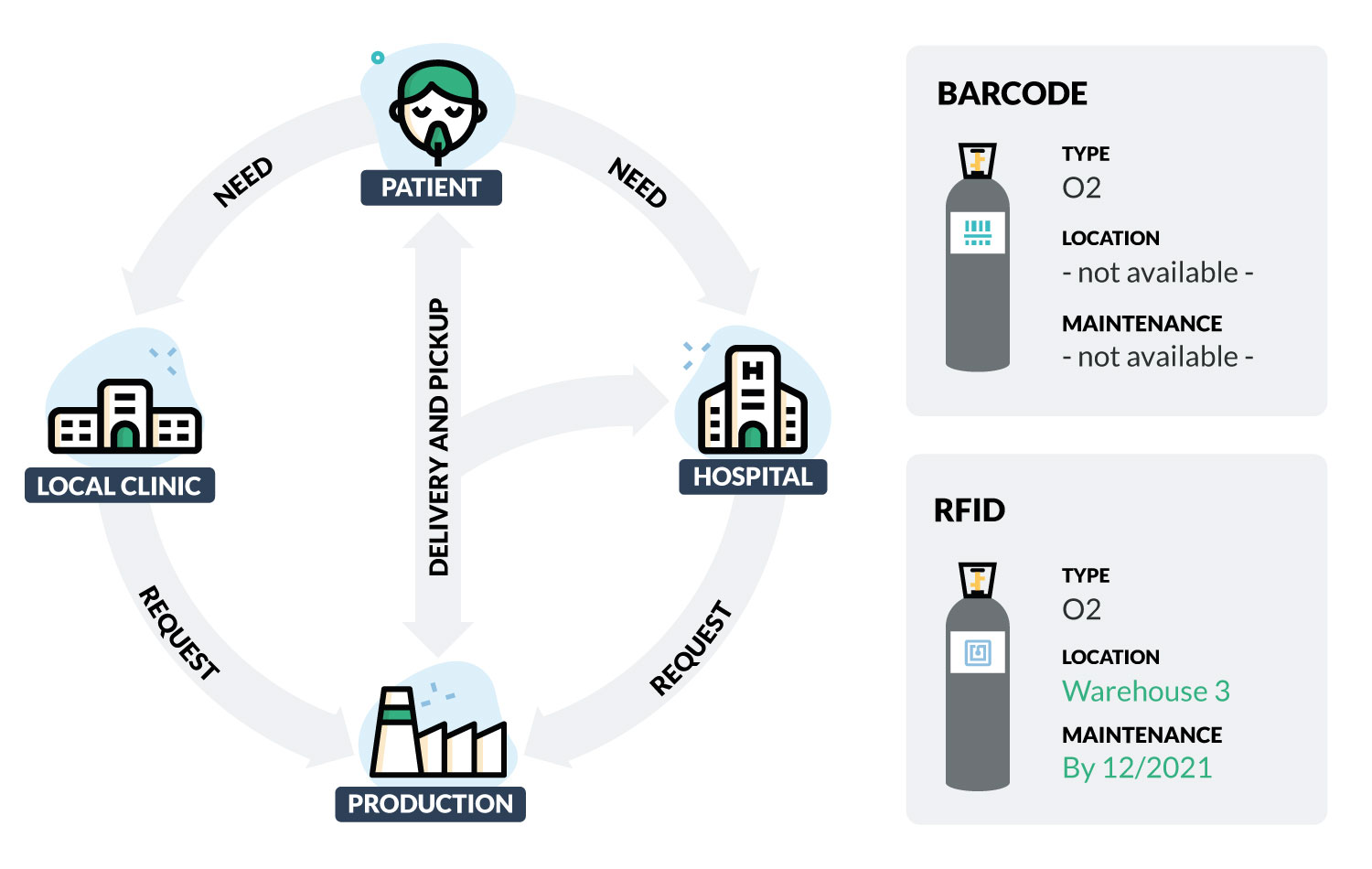

Thanks to RFID, every single cylinder is distinctively identified and traced throughout its whole life cycle: from the moment when it is filled and associated to a hospital or healthcare structure request, to its delivery either to patients or hospitals, till its return to HQ and even during every phase inside the productive plant.

It is every RFID tag univocal code to create a kind of identity card for each cylinder, containing every single piece of necessary information like, for example, its latest position, useful for its quicker traceability or maintenance expiry, essential in terms of safety. RFID systems further assist thanks to their automatic alert generation, helping companies in complying with requirements and activities.

By means of mobile reading devices or fixed reading systems, every single status change is registered: received, infilling, under maintenance, delivered… Timely information update allows companies to obtain a more accurate and punctual monitoring of their assets, also implying economic saving thanks to the reduction in the number of missing containers and therefore their higher utilization.

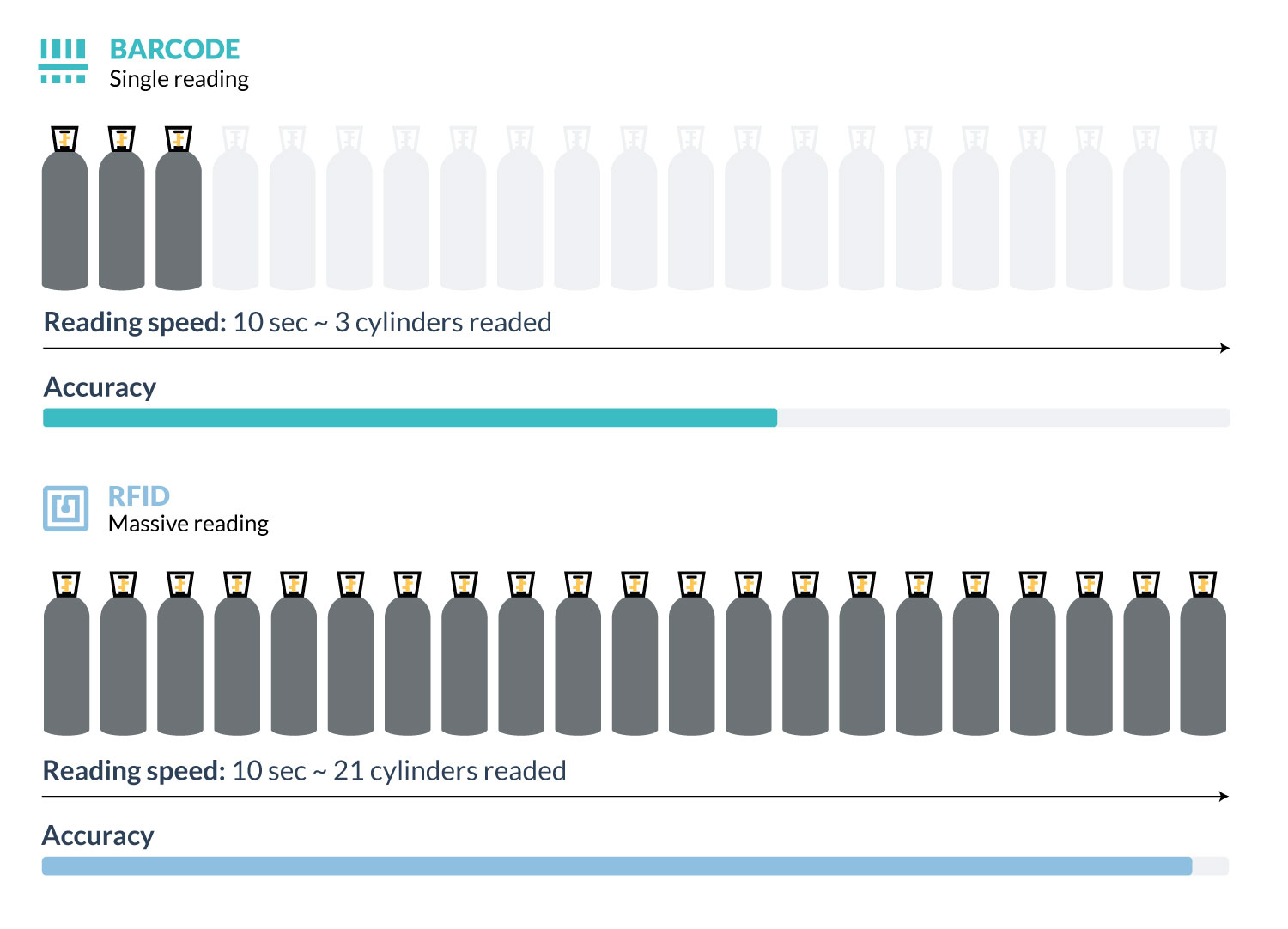

From our experience side by side with important players in this field, we have been able to see first-hand the benefits RFID technology can imply in the efficiency of cylinder identification and traceability processes. In contrast to barcodes, an RFID tag does not need to be seen in order to be read, but it is the software application that governs the identification process and the events which must be triggered afterwards; besides, reading devices can continuously identify, in just a few seconds, a high number of objects (massive reading). Its result? Considerably speeding up reading operations and reducing error possibility.

Every day technical and medicinal gas industries measure themselves against safety and health: the maximum precision and attention are therefore requested throughout every phase of production and distribution processes. In this field, technologies like RFID can indeed become a most valid ally.