In a world moving at unimaginable speeds, where process optimisation is the foundation of improved business performance, errors are increasingly less tolerated, and manual input is becoming more and more challenging, there’s still a group of workers left waiting for support. I’m talking about those users who work on the move, or in conditions where having access to a computer and a fixed workstation isn’t always possible — especially when it comes to entering orders.

Take, for example, those managing kitchens or working in fresh produce and fish markets — environments where products change daily, and there’s simply no time to sit at a computer, log in, and complete an order form.

These users often don’t fit into structured order entry interfaces and don’t have the time to figure out which product variant is currently available. What’s more, they tend to have a close, personal relationship with their supplier — and they expect to be recognised immediately, relying on the history of their purchases and established habits.

An order placed under the conditions described above often:

The scenario in which these categories of workers operate has made the order entry process a manual task, entirely dependent on the experience of the operator processing it.

Because of its complexity, all the underlying logic — from recognising the customer to selecting the most appropriate product — could not easily be translated into a standard application.

Now, however, we can offer real support to these operators – and to their companies – by automating the order recognition process, leaving only the final validation to the human operator.

The benefits for companies are substantial, as it gives structure to a process that was previously highly unstructured. So how can it be done?

At Aton, we’ve always placed a strong focus on innovation — and it’s our clients who are often the first to push us towards research and development. By starting from real market experiences, we design solutions that address needs already emerging among users. This is exactly how, with the support of LLMs (Large Language Models) and the introduction of vector databases, we’ve been able to tackle this challenge: starting from an unstructured order, we can now automatically identify the customer, the products, and any order notes — and return to the operator with a pre-filled order proposal ready for validation.

This process also brings an additional implication: the need to design new interfaces for interacting with data. Current interfaces are built around a user-driven data entry model. However, such rigidity doesn’t align with emerging processes, where the combination of automation and validation calls for a different user experience (UX).

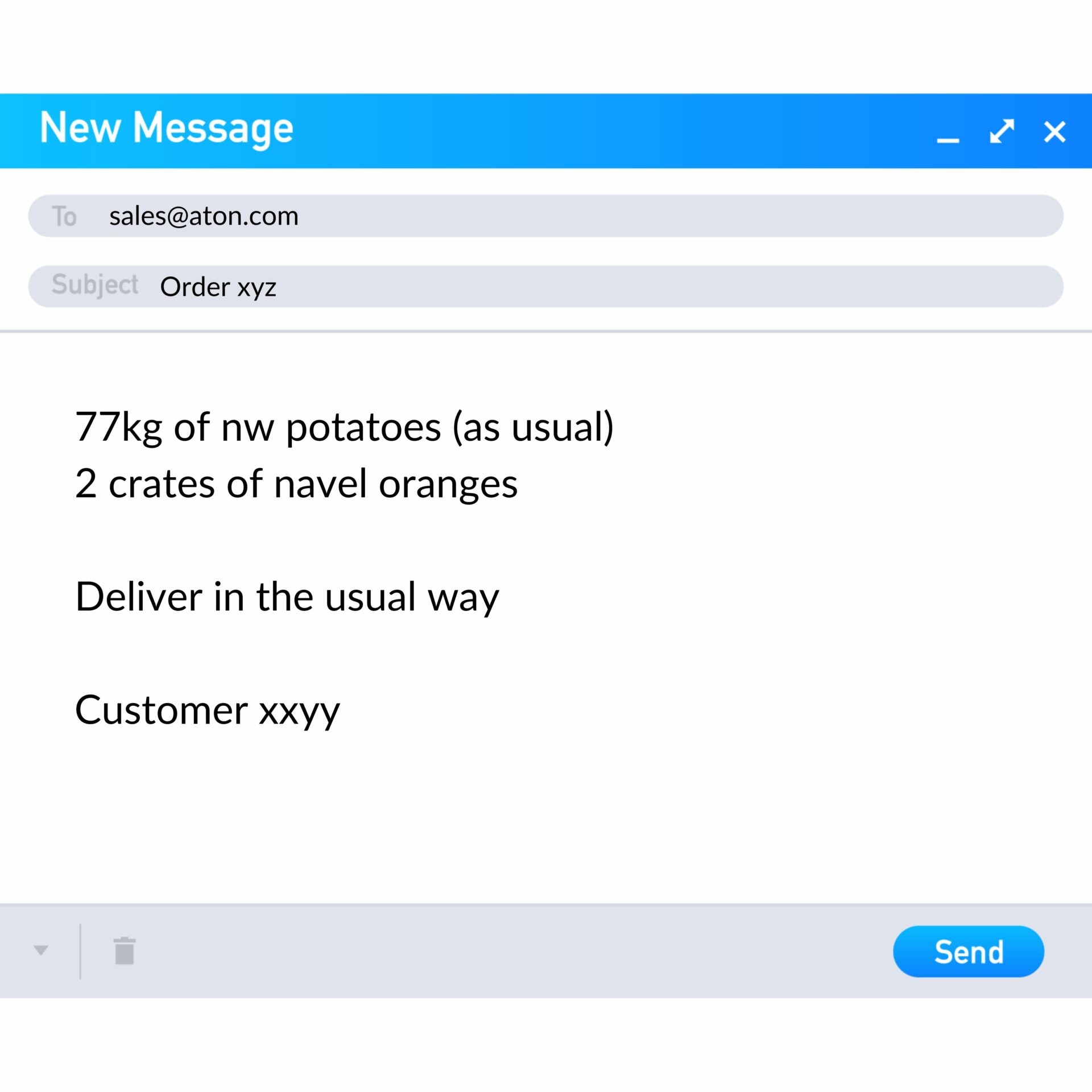

Let’s take an order as an example: how can we manage it — and support the user within the company who receives it?

Let’s first look at the critical issues within this order:

As we’ve seen, the sample order contains several natural language elements that only a human would normally be able to understand — and even then, only an operator already familiar with the customer would be able to process it, still running the risk of misinterpretation or typing errors.

By contrast, with the use of AI, we can now identify the various components of an order and represent them in a structured format.

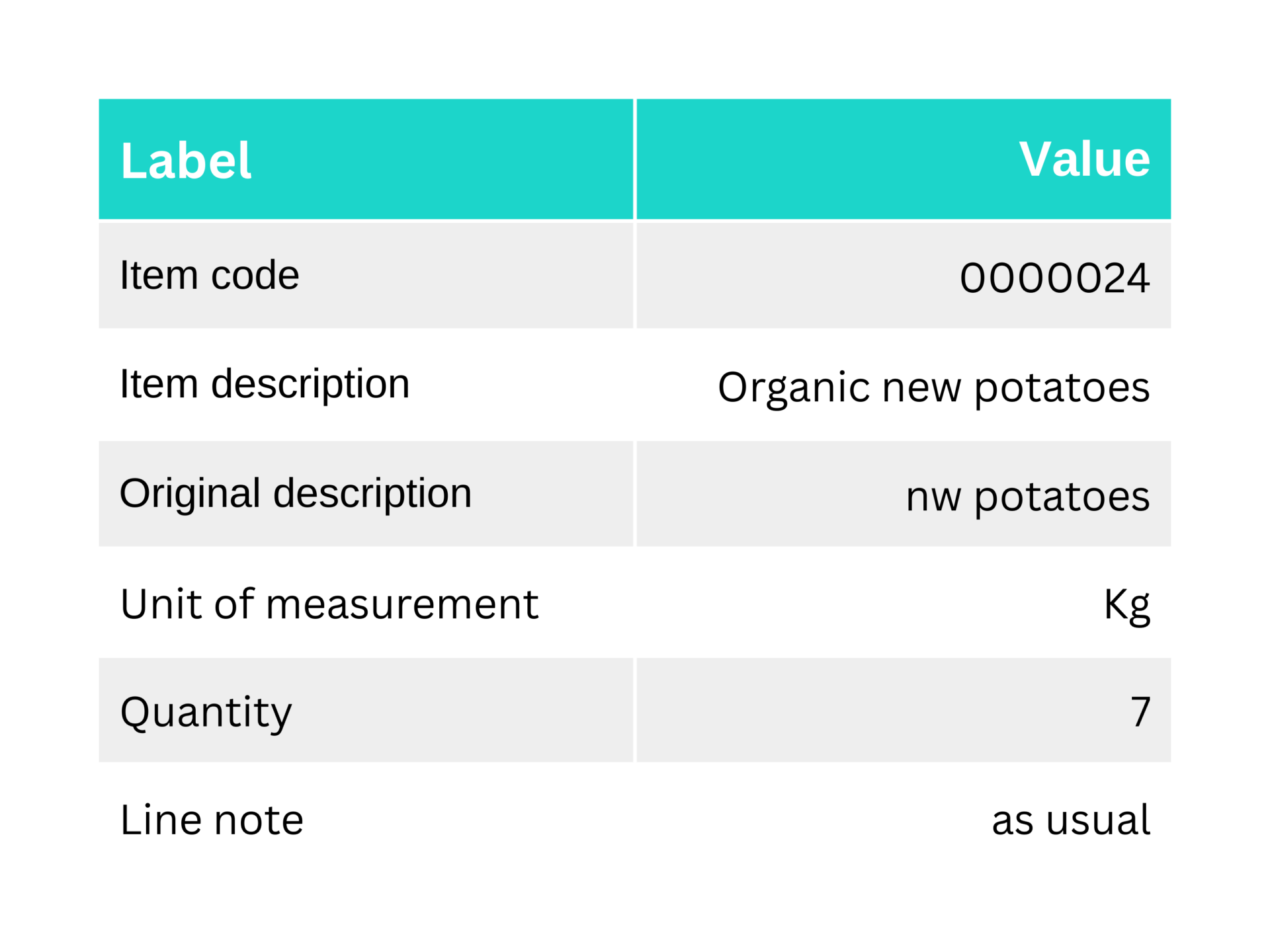

In this way, the line “7kg of nw potatoes” becomes:

Great — we’ve structured the original line, and now comes the interesting part: how do we recognise the specific product that the customer usually buys?

Some might argue that traditional database search techniques could handle the task — and they’re not wrong. But at what level of accuracy?

With semantic search in a vector database, everything changes: we can identify the product that is statistically most similar to the one requested — and, why not, even suggest relevant alternatives.

Here’s how our order line is now transformed:

We’ve worked a bit of magic — and now we’re able to pass the result through a more traditional process, which can refine it further. For example, the identified product may be unavailable, or the quantity might not match the standard packaging. At this stage, an operator steps in to validate the result and send the order for fulfilment.

So how far can we scale this process now? Starting from an email — or even a voice message (yes, we’re now talking about voice message interpretation too) — we can achieve an incredible result in just a few seconds.

That’s right: we’ve used AI to enter orders.

We’ve read and interpreted natural language, and we’ve embedded part of the customer’s knowledge and habits into an automated workflow. Not bad, right?

Bringing new technologies into the right context and using them appropriately is essential. Referring to Artificial Intelligence just to ride the trend or make headlines risks trivialising its true potential.

A technology that is easily accessible is not necessarily easy to adopt — which is why Aton invests in training people. This enables them to experiment, learn, and take solutions to the next level.

Curious about the new technologies Aton is bringing to life? Stay tuned.