The new platform for asset lifecycle management

In my previous article focusing on the distribution chain, we concluded with a question: how can we achieve comprehensive control over the entire maintenance process? Here, I provide the answer!

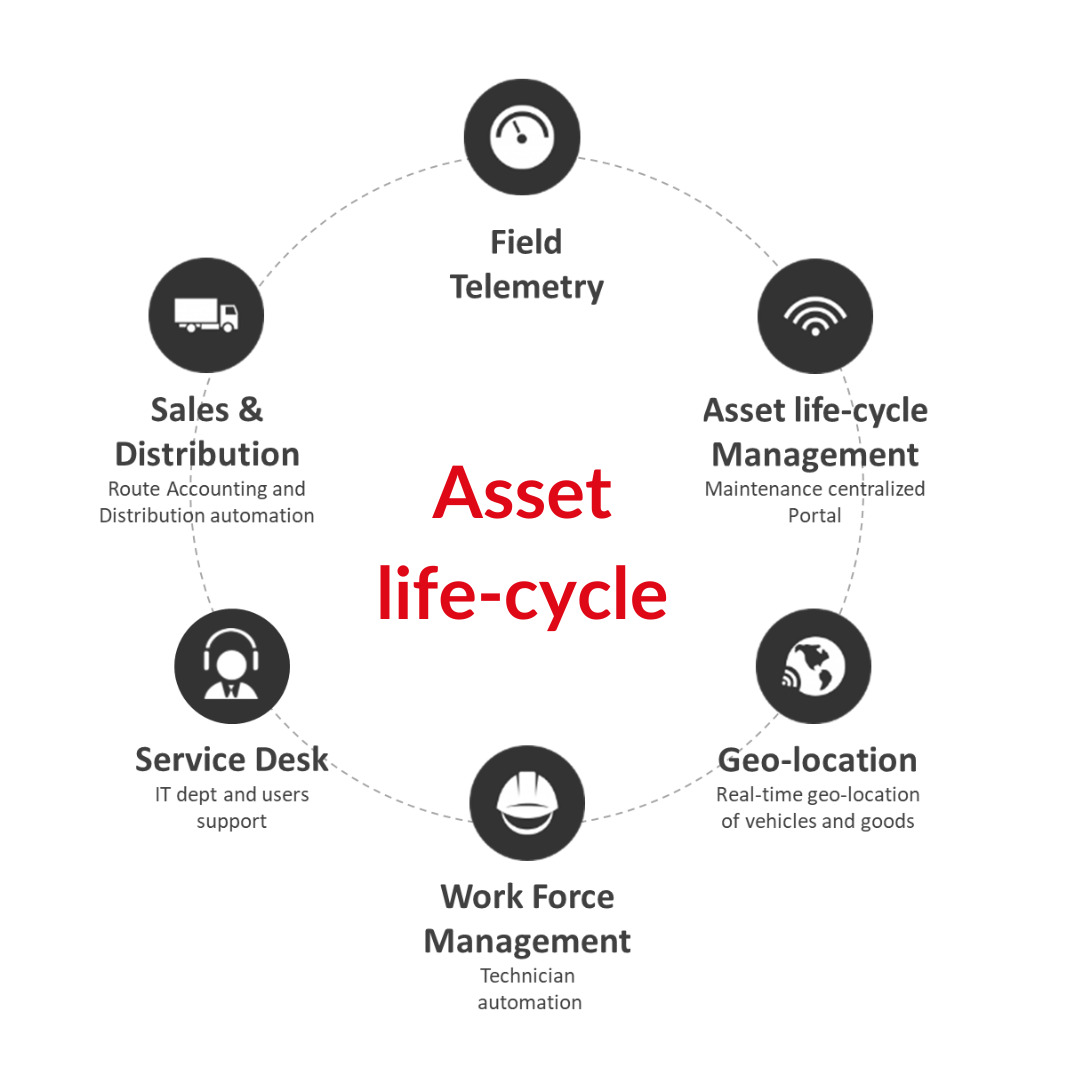

Drawing from two decades of experience with companies in the energy sector—specialising in the distribution of LPG, oil and gas, water, and technical gases—we have integrated the following pillars into the latest functional architecture of our applications for asset lifecycle management:

Let’s explore these together!

Providing users with a digital archive simplifies operations, eliminates redundant tasks in activity mapping, and offers significant operational savings—a potential game-changer for many in the sector.

Information that often gets lost in numerous Excel files on individual computers, or worse, in dusty paper folders, will now be accessible to users responsible for asset maintenance through a new, intuitive, and user-friendly interface!