.one RFID Supply Chain

The RFID solution for item traceability across the supply chain

The RFID solution for item traceability across the supply chain

.one RFID Supply Chain is the link between the physical and digital worlds. RFID (Radio-Frequency Identification) technology places the product at the centre of a journey that begins with its production, continues through sales, and reaches the end consumer.

It is the solution designed to monitor and manage every stage of the product lifecycle – even when external partners are involved.

Thanks to its flexible and integrable architecture, .one RFID Supply Chain is the ideal tool for adopting the Digital Product Passport (DPP), the digital passport promoted by the European Union to encourage transparency, sustainability and conscious consumption.

The item is traceable throughout the entire supply chain and supports the transition to the Digital Product Passport (DPP).

The proprietary .one RFID software is natively integrated with ERP, WMS and CRM systems, providing data that is always up to date and available.

Adoption is flexible in terms of technology, vendors and existing scenarios, and incremental according to project needs.

Here are some organisations that have chosen to optimise traceability with Aton

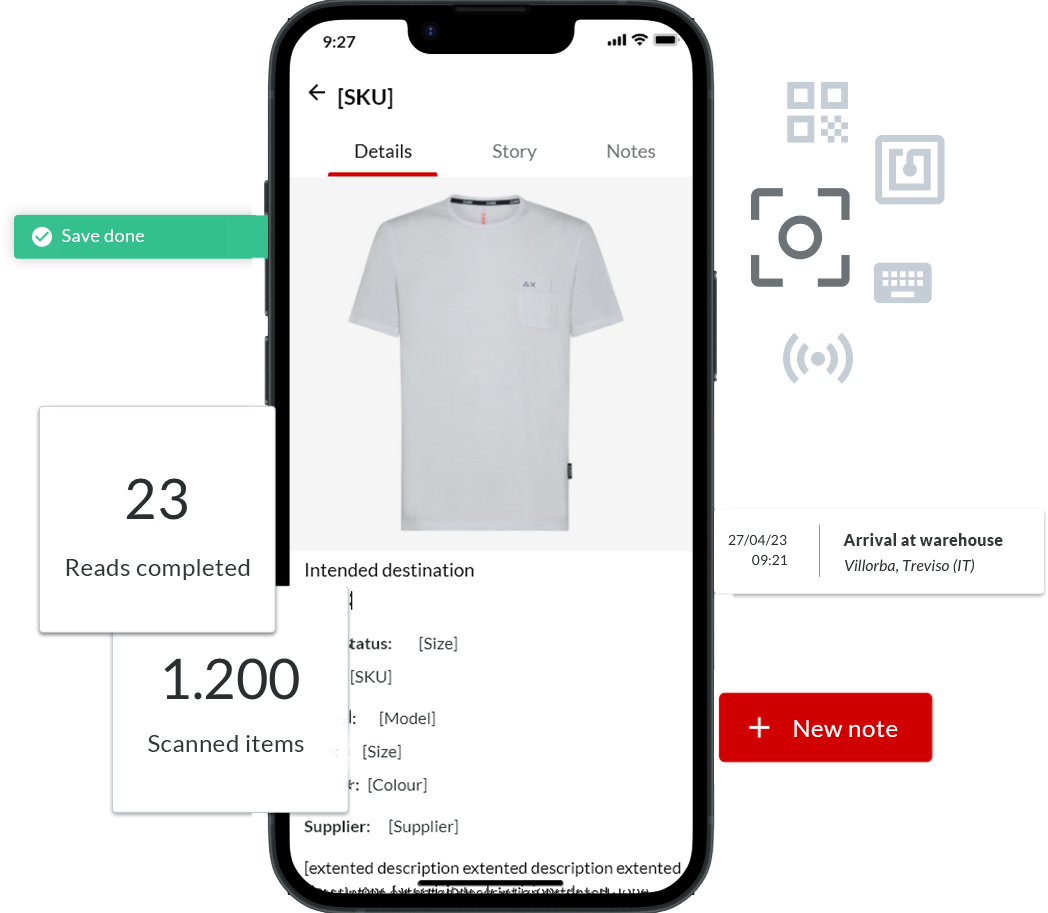

It uses QR codes, NFC chips or RFID tags to identify a product and provide up-to-date data in real time. All the information collected along the supply chain is made available.

It manages all supply chain processes for the acquisition and matching of tags involving fixed reading systems, such as tunnels, workstations, roller conveyors and mobile units with dedicated devices.

It manages all item movement processes and inventory operations through mobile devices.

It tracks every single item from production throughout the entire supply chain and makes it possible to verify that it is within the authorised distribution channel.

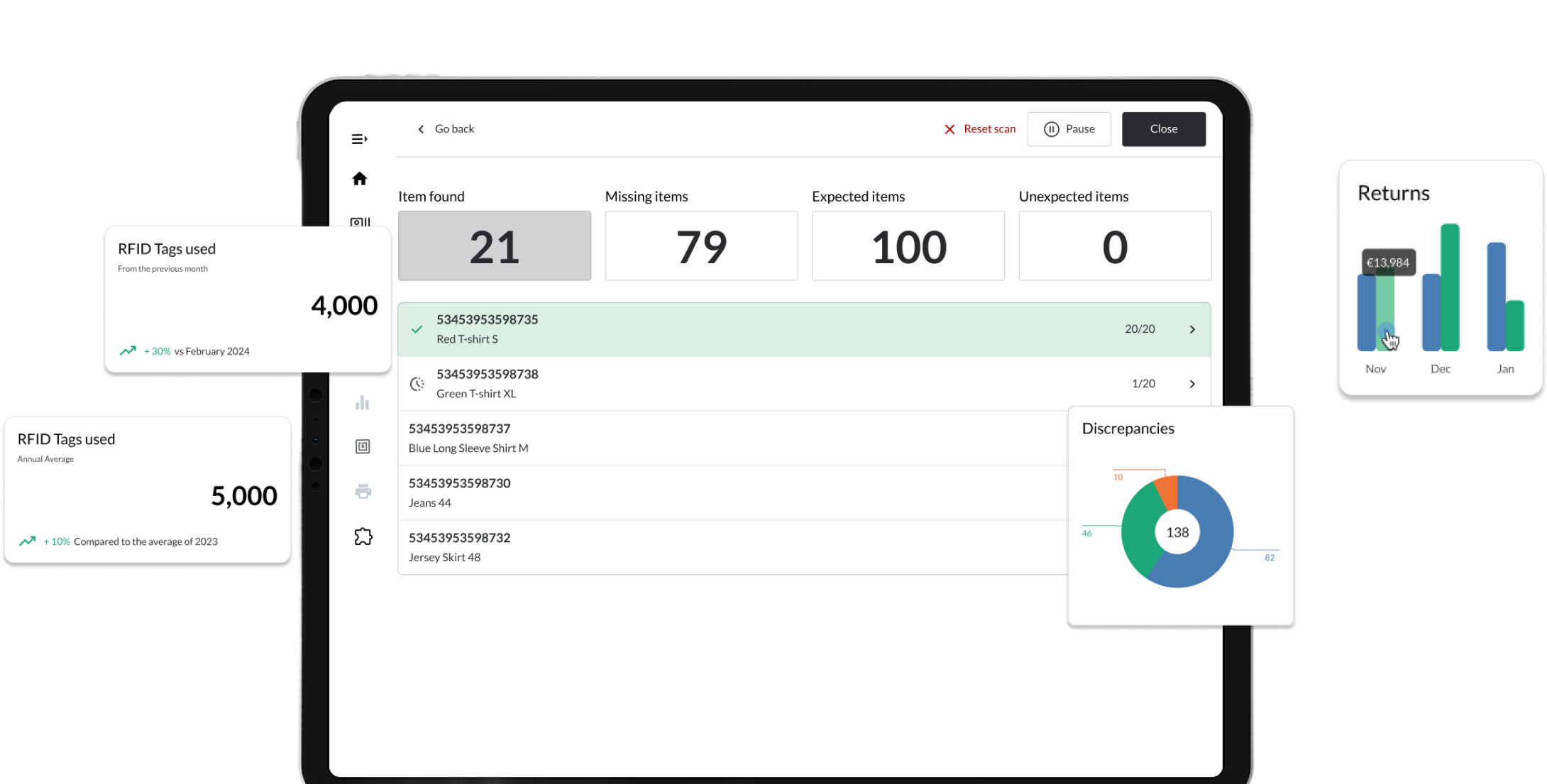

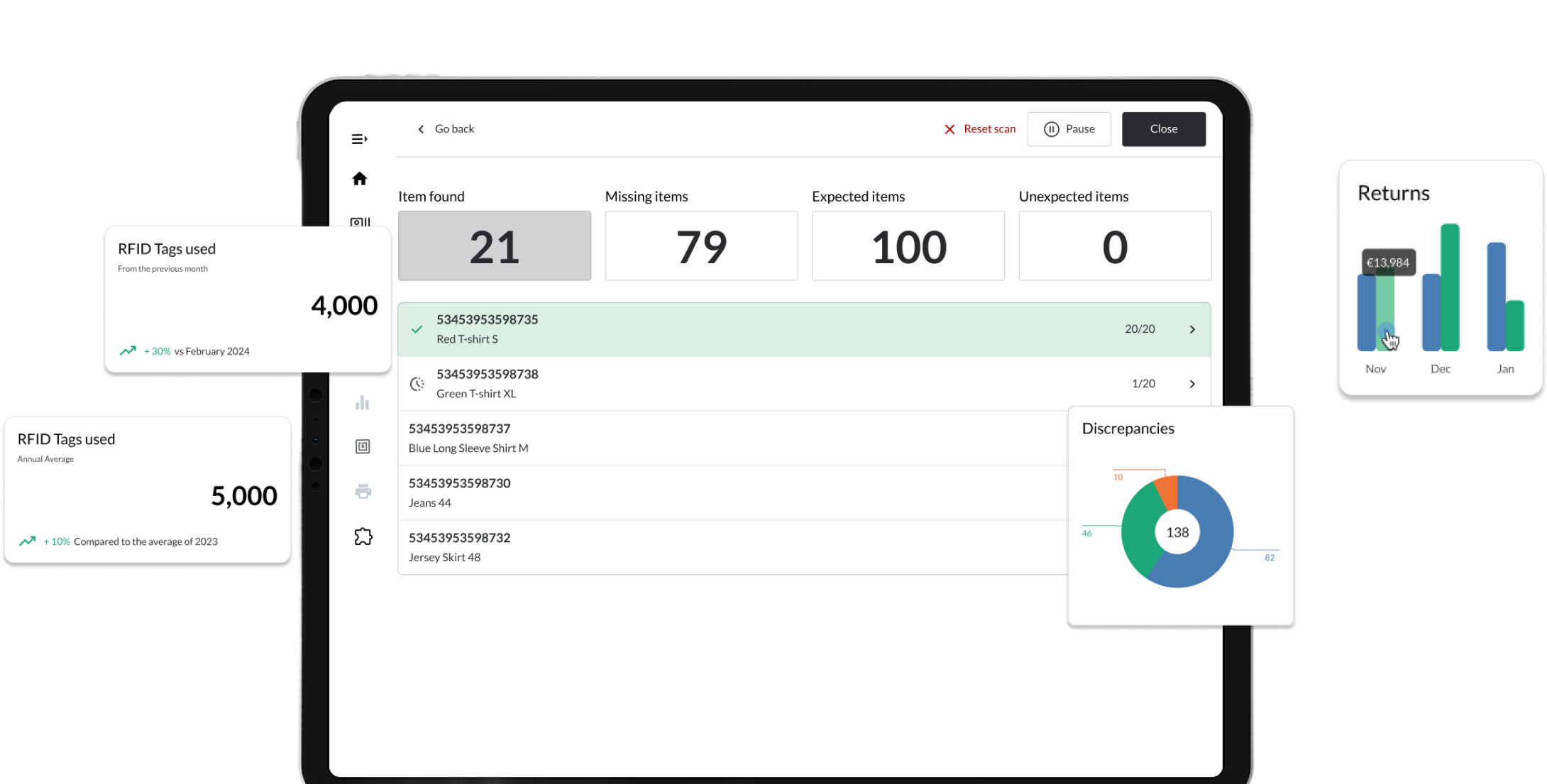

It manages and monitors all processes related to the installed modules and the data they produce—such as inventory, items sold, items transferred, and more—through dashboards accessible at any time on desktop, tablet, or smartphone.

Movement data always updated in real time.

It optimises all processes along the supply chain and allows inventory to be carried out at any time.

Facilitates DPP adoption.

All the information collected along the supply chain is available to ensure full control of the product lifecycle.

Ensures authenticity and combats the grey market.

It creates and retraces the history of a garment, ensuring its correct placement within authorised distribution channels.

Reduces out of stock.

It enables the definition of sales and merchandising strategies through the collection of valuable in-store information: sold items, tried-on items, inventory and stock levels.